Scratch Resistant Coating for Glasses: Full Guide

Have you ever thought of why some of the glasses appear to remain undistorted all these years, and why others display pockmarks after a few months? The solution is in something that you may not even notice, the scratch-resistant coating. It is that unsung hero that helps your lenses to appear new, Infocus, in focus longer, and it lasts.

My name is Laura, and in the process of using coatings that are scratch-resistant, I have found out that some are not created equal. It has various kinds of approaches to it, with different sciences, advantages, and disadvantages.

In my blog, I will take you through each of the coating types, how they each work, and the one that will suit you best.

What Is Scratch-Resistant Coating?

Scratch-resistant coating is an invisible, rather thin coating that is put on the surface of eyewear glasses to make them harder, which reduces the chances of being scratched by objects in the course of their daily use. It does not eliminate the possibility of scratching, but it substantially increases the durability of your glasses by diminishing the effects of dust, dirt, inadvertent drops, as well as cleaning friction.

It serves as a protector over your lenses and not only saves them but also saves you the hassle and money wasted on having to replace a scratched pair of glasses.

Methods

1. Silicone-Based or UV-Cured Layers

It is the ubiquitous scratch-resistant coating that you will likely encounter, and with good reason. It is cheap, everywhere, and highly viable day to day use.

How It Works

I can boil it down: basically, a hard coating is deposited on the lens surface, either compounds based on silicone or UV curable polymers. Once it is applied, it dries to a thin transparent covering.

- Silicone-based coats: You can use liquefied silicone that is hardened and made to seal.

- UV-cured paint is a process of spreading a liquid resin and curing it by using ultraviolet light.

Why It’s Effective

The coatings form a non-scratchable smooth coat which is dense to resist scratching activities by the cleaning clothes, dust, and contact with surfaces.

Pros

- Cost-effective

- Clear and no distortion of vision

- Both plastic and polycarbonate lenses work on them

Cons

- It will not prevent deep scratches due to falls or pens.

- Not all manufacturers are of quality

2. Diamond-Like Carbon (DLC) Coatings

And DLC coatings are the big guns of the scratch resistance industry to anyone in search of next-level durability.

How It Works

Diamond-like carbon layers are formed by coating a fine layer of carbon atoms on the lens in a method that resembles the hardness of diamond. Nothing to panic about, it is not real diamond dust, but the structure is very similar.

It is deposited by physical vapor deposition (PVD) or plasma-enhanced chemical vapor deposition (PECVD), which itself sounds like something out of a lab experiment (because it is).

Why It’s Effective

Carbon bonds are so strong, and when this happens in this diamond-like pattern, it makes the surface so super hard and scratch-free, almost like putting a shield on your lenses.

Pros

- Very stout and durable

- Very thin, no unnecessary weight

- Commonly applied in high-performance or sports glasses

Cons

- Higher than the normal coating options

- Not guaranteed for all forms of lenses

3. Sol-Gel Coatings

Science is interesting here. The Sol-Gel coatings are also popular since they unite nano-technology, durability, and transparency.

How It Works

Sol is a case of a liquid solution in which silica or other inorganic particles exist. This is applied to the lens and gelled and cured using a thin layer of glass-like substance.

The result? A coating that is not only hard but also chemically compounded to the lens, providing better adhesion and permanence.

Why It’s Effective

The coating will not just lie on the surface; it is chemically bound to the surface. That increases its resistance against peeling off or wearing off.

Pros

- Superb scratch resistance

- Can be mounted on anti-reflective (AR) coatings

- Excellent visibility on clarity (optical)

Cons

- Rigorous to apply in (not every lab is equal at doing it)

- It may be costlier than normal hard coating

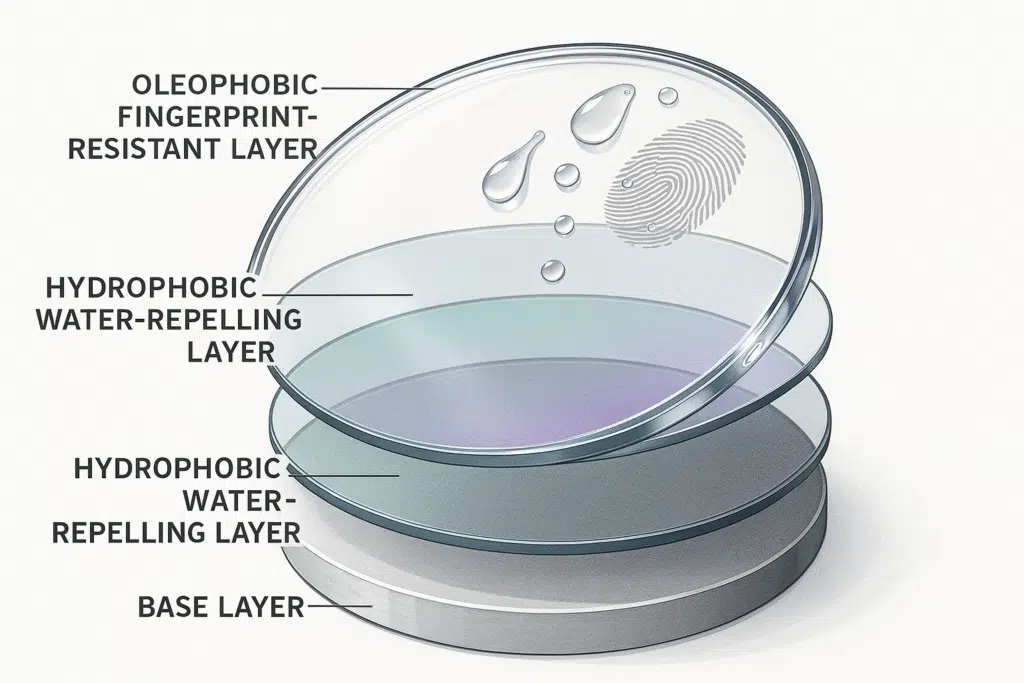

4. Multi-Layer Coatings (Hybrid Layers)

To have it all and then some, multi-layer coatings are the place of magic.

How It Works

It’s like a sandwich of protective layers:

- A hard base layer for scratch resistance

- An anti-reflective layer for better vision clarity

- A hydrophobic layer to repel water and dirt

- An oleophobic layer to resist fingerprints

There is a purpose in having layers, and each layer not only makes your lenses scratch-resistant but also makes them easier to clean and wear.

Why It’s Effective

Each layer has a function, and they make your lenses not only scratch-proof but also effortless to clean and wear a lot more cozy.

Pros

- Comprehensive protection

- Looks crystal clear

- Ideal for daily wearers who want low maintenance

Cons

- Higher cost

- If one layer is damaged, it can affect the others

5. Ion-Assisted Deposition (IAD)

For those who like their coatings to sound like something from a space lab, Ion-Assisted Deposition will be your jam.

How It Works

IAD involves bombarding the lens with ions while depositing the coating material. This creates a super-dense and tightly bonded layer.

In terms of scratch resistance, the dense structure means there are fewer weak points for scratches to form.

Why It’s Effective

The bombardment of ions assists in the increased contact of the coating and hence prevents the wearing off of the coating. It can also be easily incorporated into high-quality anti-reflective lenses to combine various advantages.

Pros

- Highly durable and stable

- Resistant to environmental wear (heat, humidity)

- Great optical clarity

Cons

- Typically more expensive

- Requires specialized equipment, so not all labs offer it

6. Spray Coating with Nanoparticles

This is the DIY-friendly cousin of the other methods, though it’s also used in professional lens manufacturing.

How It Works

The lens is coated with a spray of tiny particles of nanosize (usually silica or titanium dioxide). They fill the indentations of the microscope, enveloping the surface, exposing a layer of hard, smooth surface when dried.

These sprays may be purchased to use at home, but even better and lasting are the professional versions.

Why It’s Effective

Nanoparticles render the coating even and exceedingly thin, albeit hard. They are also engineered in order to be water repellent or anti-smudge.

Pros

- Quick application

- Can refresh older lenses

- Adds multi-functional benefits

Cons

- Home versions are less durable

- Needs reapplication over time

FAQs

What can I do to make my glasses scratch-free?

Look into getting lenses containing an applied professional scratch-resistant coating and keep them locked up in a hard case at all times.

Do they make scratch-proof glasses?

There are no glasses that would be scratch-proof; however, high-quality coatings can make glasses highly resistant.

What coating is scratchless?

DLC coatings have the best available scratch resistance.

What is the best eyeglass coating?

The scratch resistance is paired with anti-reflective, water-resistant, and smudge-proof qualities by multi-layer coatings.

Read Also: Don’t Get Scammed—Check If Gucci Sunnies Are Real Now

Final Words

Scratches can be an inconvenience you can only think about, but in the long run, they will distort the quality and comfort of your glasses. That is why it is not only an upgrade, but an investment in the ability to see what you want to see, to make your wallet less tight, and to ensure that your daily wear and tear is relieved by the proper scratch-resistant coating.

Keep in mind that there is no such thing as scratch-proof coating, but depending on your selection and fitting care, your lenses can stay clear decade after decade.